The shipping and maritime sectors are under a transformation. From digitisation to stringent environmental protection laws to changing container dimensions, new technologies, amendments, regulations etc. are continuously being added to the industry.

One of the most significant transformations in the history of shipping and the maritime sector was when the first cargo container was introduced to drastically reduce the transportation of products. Today, different container dimensions are used depending on the type of cargo.

Related Reading: History of Containerization

As of today, more than 17 million containers of different dimensions and types are used globally to make container shipping the most efficient method of transportation. These shipping containers are ISO certified, which means that they are brought into business only when they are manufactured and tested as per the specifications provided by the International Organization for Standardization (ISO) to ensure that the goods carried are suitable for multiple transportation modes, i.e. via ship, truck or rail.

Related Reading: 16 Types of Container Designs

In this article, we will discuss the important specifications of the shipping containers, including container dimensions and markings on them. The materials used for manufacturing a shipping container is either aluminium or steel, making them excellent to use for dry and packaged cargo.

The advantage of aluminium dry containers over a steel container is that the former has a slightly larger payload, whereas the dry steel containers have a slightly larger internal cube.

Related Reading: What is an intermodal container?

Following are the dimensions of a shipping container which are used in the international shipping market:

20 ft. container:

A standard ISO container of 20 ft. is the most popular of all and is used by ships of all sizes, big or small. The 20 ft container dimensions are as follows:

It can carry the maximum gross weight of 30480 kg / 67200 lbs for general purpose containers and up to 45,000 kg (99,207 lbs) for flatracks.

A 20 ft reefer container has a payload capacity of 27, 400kg

40 ft container:

40 ft container dimension offer double the volume as compared to a 20 ft container, and costs just 15-25% more than the later. It makes the 40 footer, the most cost-efficient shipping container for goods carriage by ship.

It can carry the maximum gross weight of 30480kg / 67200lbs for general purpose containers, up to 60,000 kg (123,276 lbs) for Flatracks and 35,000 kg (77,161 lbs) for reefer containers

45 ft container:

45 ft containers provide slightly better cubic feet capacity than a 40 ft container giving valuable extra space to the shipper giving the following advantage:

- Efficient Cargo Transportation

- Potentially Lower Transport Cost

The payload capacity of 45 ft container is almost similar to a 40 ft container.

The above specifications are a representation of the commonly used containers. Specific container dimensions and capacity the ISO containers may vary depending on the manufacturer, the age of the container, and the container owner.

Related reading: Handing Containers On Ships: Dimensions, Markings And Bay Plan

There are other dimension containers available in the market which are mostly used for road and rail transportation – 8 ft, 10 ft, 53 ft, 60 ft.

Markings on a container:

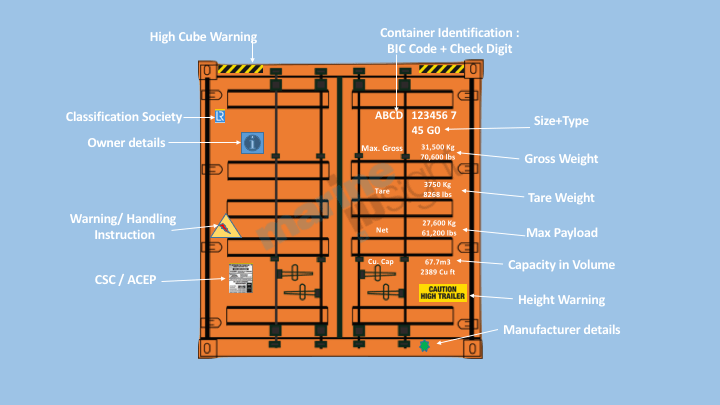

The standard for the coding, identification, and marking of containers is DIN EN ISO 6346, dated January 1996.

Following are the different markings provided in an ISO container.

1) Container Number – The container marking is the primary identification marking on the door end of an ISO container. It consists of seven numbers and four letters, which are allotted by the ISO to identify every container to its owner. The number is unique for everyone and is registered for the records with Bureau International des Containers (BIC), Paris.

Suppose the container number as shown in the diagram is-

ABCD 123456 7

Here the first 3 letters, i.e. ABC denotes- Code for the Owner of the container

The 4th letter D provides -the container category

The first six numbers, i.e. 123456 is – the serial numbers of the container

The last number, i.e. 7 is- the check digit which is used to validate if the owner or product group code and the registration number have been accurately transmitted.

Related Reading: How are shipping containers made?

2) Owner’s Logo – The shipping line or container vendor’s logo/name is provided on the end door.

3) ISO Code: The ISO container code is stencilled below the container identification number and provides the details of the type of container, i.e. GP (for general purpose), DV (for a dry van) etc. and also denote the size of the container. E.g. if the ISO code below the container identification number is 45 G0, the first number, i.e. “4” denotes the code length (40 ft) and the second number, i.e. “5” is the code for width. The last two alpha-numeric character shows the type and subtype of the ISO container.

4) Weights & Payload: All the details of container weight and cargo weight are also marked in the end door.

– The weight of the shipping container: The true weight of an empty container provided by the manufacturer post the manufacturing process.

– Payload: This is the maximum cargo weight an approved ISO container can carry

– Gross Weight: The total weight of container and cargo within the safe limit

5) Approved Classification society label – Before the container is used by a shipping company for cargo transfer; it is tested for seaworthiness and compliance to the ISO standards by an approved classification society. The label of the class is also provided on the end door of the container.

Related Reading: What is the international association of classification societies?

6) Cube or volume – The cubic capacity or the volume of the container is marked in the end door.

7) Warning and Operational Signs: The container may carry various warning labels and signs depending upon its type and cargo it is carrying. E.g. a heightened container will contain the height or warning stripes on the top part of the container. Similarly, a container carrying hazardous cargo will carry a warning sign about the type of hazard or cargo associated with it.

Related Reading: 8 Things Deck Officers Must Know While Handling Packaged IMDG Cargo

8) Certifications – Different certificates which are occupied by the container needs to be displayed using plates, such as:

CSC plate: Container Safety Convention plate showing the ISO container has been inspected and tested by approved authorities. It also contains details of the owners and other technical specifications.

ACEP: It stands for Approved Continuous Examination Programme and is provided in the container. This is a safety program for shipping containers, wherein the container under it has to undergo an extensive inspection in a container depot every 30 months of its service. The container owner will renew the ACEP every 10 years.

Related Reading: What is Container Security Initiative And How Does It Work?

For a seagoing professional or anyone who wants to transport cargo through shipping containers, it is very important to understand different container dimensions, nomenclature, signals, symbols and signs displayed not only in various parts of the ship but in the cargo containers too.

If you think we missed some or should add more specifications related to the shipping container, please provide your valuable comment below.

Ref: MarineInsight